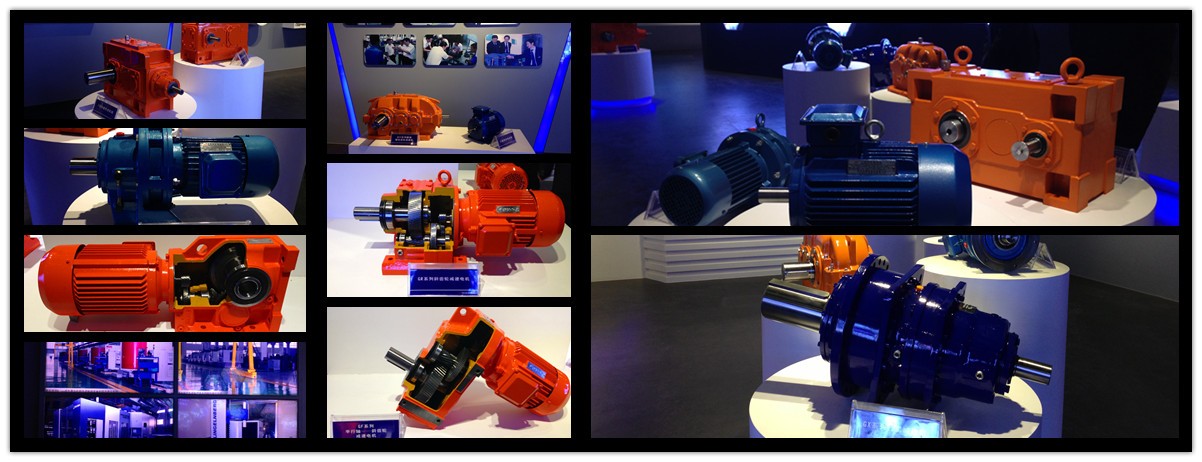

The gearbox is subjected to the force from the wind wheel and the reaction force generated during the gear transmission. The top 10 gearbox manufacturers in india.It must have sufficient rigidity to withstand the force and torque to prevent deformation and ensure the transmission quality. The design of the gearbox housing should be in accordance with the layout, processing and assembly conditions of the wind turbine power transmission, and easy inspection and maintenance.The top 10 gearbox manufacturers in india. With the rapid development of the gearbox industry, more and more industries and different enterprises have applied gearboxes, and more and more enterprises have grown stronger in the gearbox industry.

According to the modular design principle of the unit structure, the gear box greatly reduces the types of parts and is suitable for large-scale production and flexible and variable selection.The top 10 gearbox manufacturers in india. The spiral bevel gear and the helical gear of the reducer are all carburized and quenched with high-quality alloy steel. The hardness of the tooth surface is up to 60±2HRC, The top 10 gearbox manufacturers in india.and the precision of the tooth surface grinding is up to 5-6.

The bearings of the transmission parts are all domestic famous brand bearings or imported bearings, and the seals are made of skeleton oil seals; The top 10 gearbox manufacturers in india.the structure of the speaker body, the larger surface area of the cabinet and the large fan; the temperature rise and noise of the whole machine are reduced, and the reliability of operation is improved.

The top 10 gearbox manufacturers in india.The transmission power is increased. Parallel axis, orthogonal axis, vertical and horizontal universal box can be realized. The input mode includes motor coupling flange and shaft input; The top 10 gearbox manufacturers in india.the output shaft can be output at right angle or horizontal, and solid shaft and hollow shaft and flange are available.

The planetary gearbox manufacturers in satara.Planetary gearbox, or planetary gearbox, is also called a gearbox. Its structure is a mechanism in which a plurality of planetary gears rotate around a sun gear. The planetary gearbox manufacturers in satara.It is also a mechanism that reduces the transmission speed ratio and increases the torque of the motor proportionally.

Features: Compared with similar common tooth physics box, it has a smooth transmission, large bearing capacity, small space and large transmission ratio, especially life. The planetary gearbox manufacturers in satara.If the gear is steel, the life can reach 1000Y, the volume is small, and the appearance is beautiful.

The planetary gearbox manufacturers in satara.Application: Planetary gearbox, widely used, initially with the motor, in addition to the micro gear motor, also used in the office automation of the sunshade industry, smart home, production automation, medical equipment, financial machinery, game consoles and other fields.The planetary gearbox manufacturers in satara. Such as automatic curtains, smart toilets, lifting systems, money counters, advertising light boxes and other industries.

At present, the planetary gearboxes on the market mainly have diameters of 16MM, 22MM, 28MM.32MM, 36MM, 42MM, and cooperate with the motor. The planetary gearbox manufacturers in satara.The function can reach the load torque: 50KG 1-30W Load speed: 3-2000RPM

Planetary gearbox is an important component widely used in mechanical transmission. The planetary gearbox manufacturers in satara.When a pair of gears meshes, there is inevitably a tooth pitch, tooth shape and other errors. During the operation, an meshing impact will occur and a gear meshing frequency will occur.The planetary gearbox manufacturers in satara. Noise, frictional noise occurs between the tooth faces due to relative sliding. Since gears are the basic part of the gearbox drive, reducing gear noise is necessary to control gearbox noise. The planetary gearbox manufacturers in satara.In general, the causes of gear system noise mainly have the following aspects:

1. Gear design. Improper parameter selection, too small coincidence, improper or no shape modification, and unreasonable gearbox structure. In the gear processing, the base section error and the tooth profile error are too large, the flank clearance is too large, and the surface roughness is too large.

2. Gear train and gearbox. The assembly is eccentric, the contact precision is low, the parallelism of the shaft is poor, the rigidity of the shaft, the bearing and the support is insufficient, the rotation precision of the bearing is not high, and the gap is not appropriate.

3. Input torque in other aspects. Fluctuation of load torque, torsional vibration of the shafting, balance of the motor and other transmission pairs, etc.