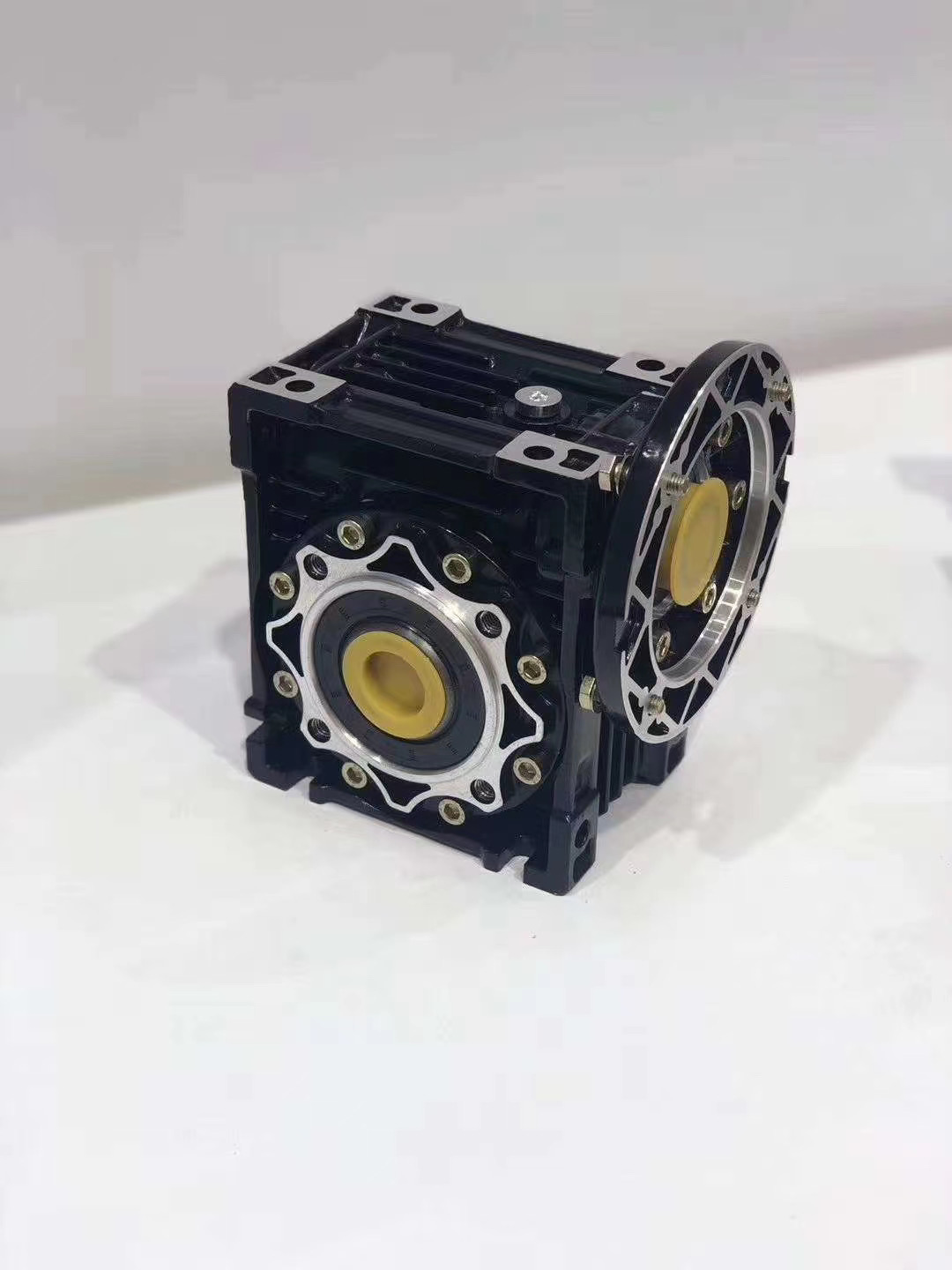

Gearbox motor frame maker pursue quality and build better gearbox motor frame products

What is so special about this project is that we're dealing with a high speed gearbox and we had three weeks to finish the gears and the pinions I am happy to say that we succeeded at this. with all the help from engineering, our colleagues in the gearbox motor frame maker, the turning machinists, the milling machinists. Everybody has been giving a 110% to fix this project.

Another thing that makes this

project so special for us is the requirements for testing the gearbox. It is a

high speed gearbox, and we have reconstructed one of our own testing gearboxes

to reach the high rpm. And to do that we have completely renewed the internal

parts, we produced new plain bearings and measured everything. And all that had

to be done while gearbox motor frame maker were also fabricating the new

pinions for the client's gearbox.

We can test gearboxes more effectively and more efficiently. Our test stand is capable of testing gearboxes up to 1800 rmp, so for this project we have developed our own speed up gearbox. This gearbox also has an external oil system, it's equipped with a lot of sensors to monitor the vibrations and temperatures. And all of that is done so that we're able to test-run the client's gearbox. At this point we're just about to start run the tests, quite exciting but I think that it will run just fine. At this moment we're test-running the gearbox and the bearings still get to some high temperatures, so we're making sure that the oil is cooled with an extra oil cooler.

Enter your text here ...

Related Posts

By accepting you will be accessing a service provided by a third-party external to https://www.guomaodrive.com/

Comments