How the gearbox motor conveyor for sale?

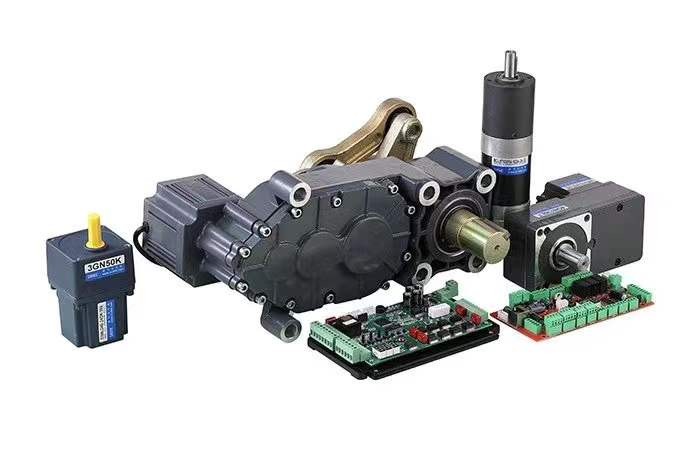

We will discuss the differences and give information on how to select the proper gearbox for your application. First the: general purpose aluminum worm gearboxes, next the general purpose cast iron worm gearboxes and last: the general purpose cast Iron helical inline gearboxes. What does a gearbox do and why would someone need one? Gearboxes, also known as enclosed gear drives or speed reducers, are mechanical drive components that can control a load at a reduced fixed ratio of the motor speed.

Typical applications are used with electric motors for reducing the output speed and increasing torque. Gearboxes are used on conveyors, packaging machines, rotary tables and more! Helical gearboxes offer less vibration, wear, noise and tend to have a longer life. Helical Gearboxes are the most expensive, so the question is: what is the trade-off between the price and cost savings through efficiency and is less vibration, wear, noise and longevity important in your application?

Worm gearboxes are more commonly used where large gear reductions are required. The design allows the worm to turn the gear, but the gear cannot turn the worm giving a braking or locking style feature. These next two models are both Worm Gearboxes and contain a worm (gear type) on the input shaft, and a mating gear on the output shaft. Worm gearboxes also change the drive direction by 90 degrees. Fill up from here at the proper level and then lastly we'll reconnect the conduit box connections, then the main power source after that and we're good to go.

In hac habitasse platea dictumst. Curabitur eget dui id metus pulvinar suscipit. Quisque vitae ligula laoreet, scelerisque leo quis, facilisis metus. You want to be very careful with this step because some motors can be extremely heavy, so you want to make sure you secure it to the proper rigging that meets all safety regulations. The next most common problem on our drive unit would be basically, gearbox and motor one or the other so your system's gone down and you need to figure out what's going on.

Gearbox Motor Conveyor for Sale

There we go

It's key to complete the step properly to reduce the chance of any seal leaks later down the road. We apply Loctite to the reducer face by looping a bead around all the bolt holes and cutouts never applying the sealant to the motor surface itself and once we've gone all the way around the holes like so we're just going to connect the dots.

Gearbox Motor Conveyor for Sale

There we go

We're gonna take our new machine here come at an exaggerated angle making sure that the teeth line up and that angle enables the gear teeth to mesh properly like you see in this assembled unit here. Now we're ready to install the nuts or bolts to the assembly so you want to be sure to tighten them to the proper torque setting in an opposed pattern always starting closest to the mounting feet of the reducer.

Related Posts

By accepting you will be accessing a service provided by a third-party external to https://www.guomaodrive.com/

Comments