Speed reducer gearbox design application that we can supply and manufactures

Description

1.Introduction

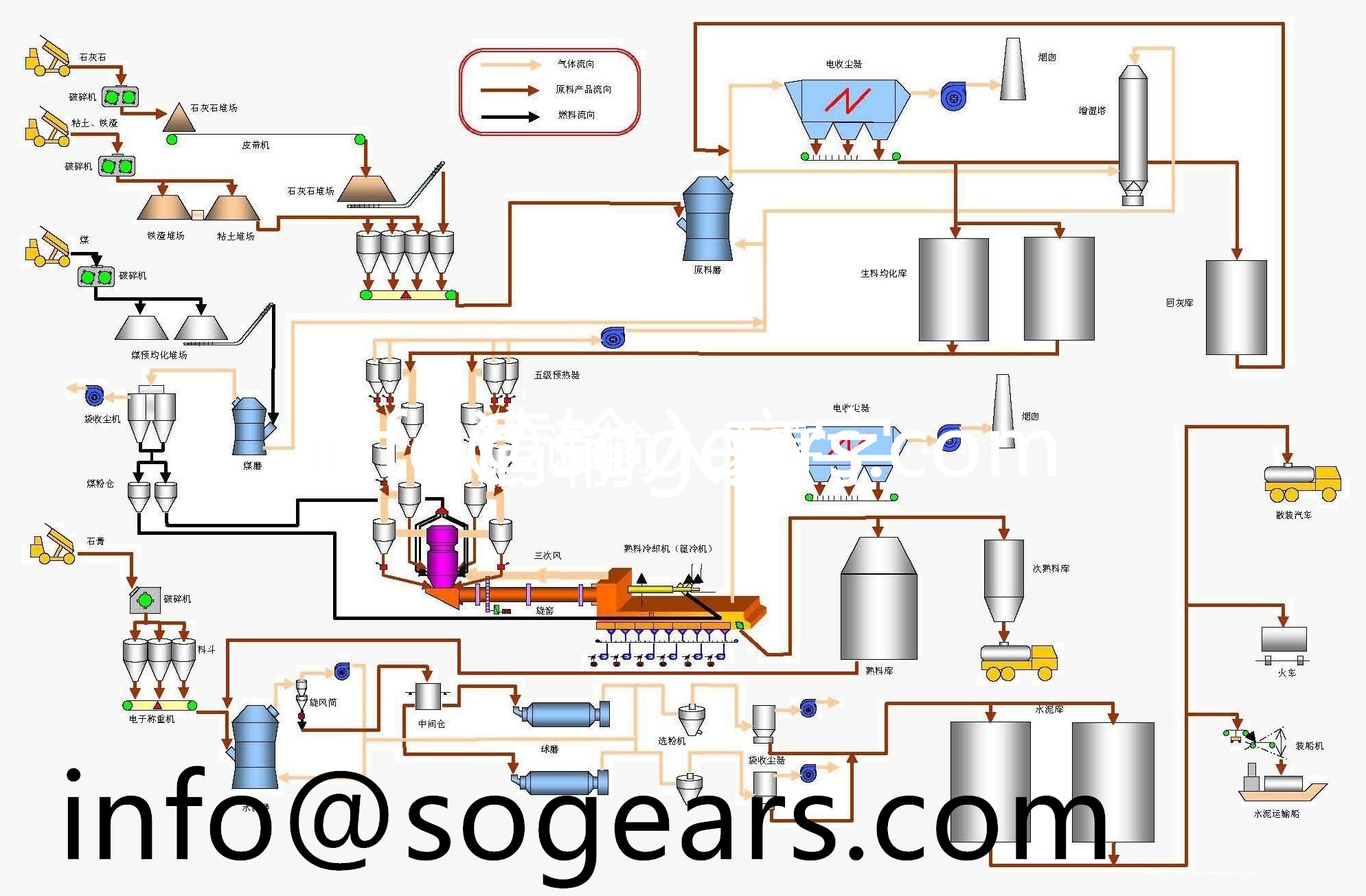

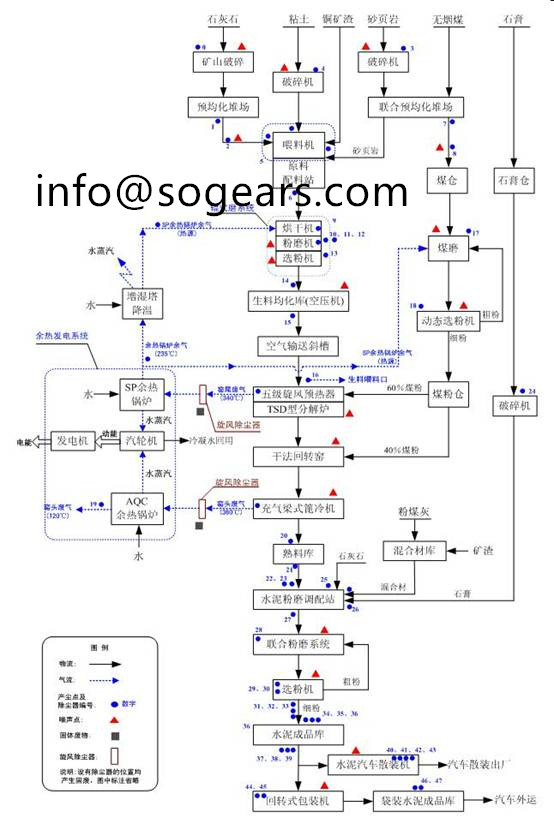

Cement production line is a complex production line specializing in the production of cement production line. This production line mainly consists of the processes of crushing and preparation homogenization, raw material preparation homogenization, preheating decomposition, cement clinker burning, cement powder grinding and packaging,Speed reducer gearbox design application, each of which is an independent and interrelated whole.

2.Process flow of cement production

(1) The raw material has been one of the more important is the field in raw material storage process, with scientific material piling and taking technology, to achieve the initial homogenization of raw material, make the raw material yard and the function of storage and homogenization.Speed reducer gearbox design application make it easy.

- Cement production process, each producing one ton of Portland cement equipment grinding at least 3 tons of materials (including all kinds of raw materials, fuel, clinker, gypsum, mixture), according to the statistics, dry process cement production line of grinding operation need to consume power accounted for about 60% of the entire factory power above, of which more than 30% of raw material grinding, grinding coal accounts for about 3%, accounted for about 40% of cement grinding. Therefore, rational selection of grinding equipment and process flow, optimization of process parameters, correct operation, Speed reducer gearbox design application and control of operation system are of great significance to guarantee product quality and reduce energy consumption.

- Preheat and part of the raw cement machinery(including Speed reducer gearbox design application ) decomposition are done by preheater, instead of rotary kiln features, to shorten the length of kiln back, at the same time make the furnace heat transfer process of the gas accumulation condition material, moved to the inner state of suspension preheater, under slurry is able to discharge of hot gas well blended with stove, gas increases the contact area, heat transfer speed, high heat exchange efficiency, improve production efficiency, reduce the clinker calcining kiln system heat loss.

- Cement machinery is the final process of cement manufacturing, but also a lot of power consumption process. Speed reducer gearbox design play an important role. Its main function is to grind the cement clinker powder to the appropriate particle size, form a certain particle gradation, increase its hydration area, accelerate the hydration speed, and meet the cement paste condensation and hardening requirements.

Speed reducer gearbox design application

With Best Regards,

Candy Hao ( Sales Department; Miss. )

NER GROUP CO.,LIMITED

Yantai Bonway Manufacturer Co., Ltd

Tel:+86-535-6330966

Mobile:+86-15192224647

http://www.sogears.com/

https://twitter.com/gearboxmotor

https://www.facebook.com/sogears1993

Viber/Line/Whatsapp/Wechat: 008615192224647

E-mail:

Add:No.5 Wanshoushan Road Yantai city Shandong Province, China(264006)