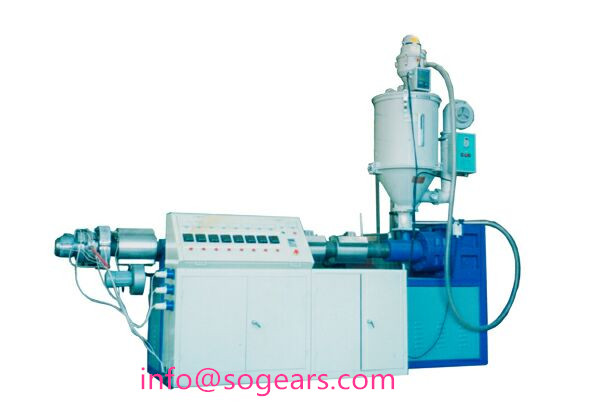

Blowing Machine Single Screw Gear Reduction Unit

The film blowing machine is mainly composed of an plastic machinery industry extruder gearbox, a machine head, a die, a cooling device, a foam stabilization frame, a herringbone plate, a traction roller, a winding device ect.

- The extruder is mainly composed of screw, barrel feeding hopper, deceleration and High efficiency AC electric motor. The driving motor adopts electromagnetic speed regulating motor (also can be used with variable frequency motor), and the Single Screw Gear Reduction Unit is driven by the belt drive to make the screw rotate in the barrel; The plastic which melts the plastic particles of the hopper under external heating is squeezed from the die die through three-pass filtration.

2.The unit adopts advanced spiral die structure. According to the special characteristics of high pressure, low pressure, mixed material and recycled material polyethylene material, the spiral angle, the back slope angle, the fixed angle length and the die opening degree are designed. Technical parameters, selected and tested by multiple comparison tests,

- The cooling device consists of a cooling air ring, a duct, a blower, etc.

Single Screw Gear Reduction Unit - The traction consists of main components such as the traction frame, the herringbone plate, the traction roller, the take-up mechanism and the traction motor.

5.The general unit is equipped with an organic group operation cabinet. The total button is connected to the main power supply to open the main switch of the AC induction 1500 rpm electric motor. The splitter switch can be used to control the fuselage and the tee, and the buttons are electrically heated. The key parts of the two sets of coils are thermocouples. Automatic temperature measurement and automatic temperature control. During normal production, the temperature can be automatically controlled to ensure stable and reliable production process.

Performance:

- The screw adopts the most advanced alloy spraying technology. After precision machining, the hardness is higher, the corrosion resistance is better, and the service life is longer. It is 2~3 times of the life of the nitriding treatment screw;

- The long diameter to diameter ratio of the screw is large, the plasticizing ability is strong, the temperature distribution is uniform, the temperature is controlled automatically, and the blown film has a bright and uniform product with good performance;

- The whole new design ZLYJ single shaft plastic gearbox is compact in structure, stable in operation, single-arm structure, economical and practical, and the traction device is integrated and can be adjusted and lifted automatically;

- Adopt advanced frequency conversion technology, high efficiency and energy saving;

- The form of curling is various and can be arbitrarily selected.

Single Screw Gear Reduction Unit

With Best Regards,

Cherry Zhang ( Sales Department; Miss. )

NER GROUP CO.,LIMITED

Yantai Bonway Manufacturer Co., Ltd

Tel:+86-535-6330966

Mobile:+86-18865558975

http://www.bonwaygroup.com

https://twitter.com/gearboxmotor

https://www.facebook.com/ner.sogears.1

Viber/Line/Whatsapp/Wechat: 008618865558975

E-mail:

Add:No.5 Wanshoushan Road Yantai city Shandong Province, China

By accepting you will be accessing a service provided by a third-party external to https://www.guomaodrive.com/

Comments