Parallel Shaft Mounted Gear motors

Description

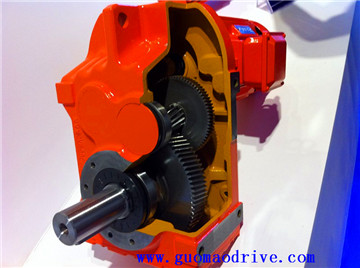

Parallel Shaft Helical Gearmotor

Parallel axis Helical Gear-units, gear motor, Parallel Shaft speed-reducer, helical gearmotor

®Helical Gearmotor Designation

Example: GF(F)77-Y1.5-4P-52.07-M2-Ø300-270°-3

GF: Parallel Shaft Gear motor

(F): None-Solid axis, F-flange with solid sleeve, A- hollow axis. H-Hollow bore with shrink disk, A/HT- Torque-arm mounted (F17...R77)- Combined types

SZ...AD- Input solid axes

77:Gearhead model number

Y1.5: 1.5kw standard electric motor.

4P: 4Pole motor, 2P-2Pole motor, 6P-6Pole motor, 8P-8Pole motor.

52.07: Gear reduction ratio

M2: Mounting way

Ø300:External diameter of flange (if there is a flange)

270°: Terminal box position

3:Position of cable entry

®Parallel shaft Gear motor Parameters

Power range: 0.12-200kW

Output speed(r/min): 0.05 - 752

Output Torque(N.M): Top to 18000N.m

®Parallel Shaft Helical Gearmotor Features

Fluorine rubber oil seal prevent leakage.

Good value for money and less maintains

Large torque,smooth startup,high efficiency

Noise Level: Low type 65-75 Db, Smooth and stable in run

Material: Carburized gears & shafts and gears HRC58-62

Working: 24 hours continuous available and live axle forward reverse

Output way:Hollow with keyed connection, shrink disk, splined ,solid axle etc.

Bearing: China standard. But SKF, FAG, NSK, TIMKEN, NTN, KOYO, C&U is a aviable if need

Atmosphere: Well ventilated location, free of corrosive gases, explosive gases, vapors and dust.

®Parallel shaft gearmotors Application

•Chemical & recycling• Conveyors • Food Machinery

• Mixers •Coat & Mining • Poultry Plants • Construction Equipment

• Paper Mills •Recycling Machines • Rotary Feeder • Textile Logistics

•Hoist & transport •Harbor & ship building •Harbor & ship building

•Cement & material •Electric power& energy •Coal & Mining • Wastewater Treatment

®We will help you

● Providing correct gearhead and combined gear-units to meet your application needs;

● Lowering maintenance cost and lifting operation efficiency;

● Improving production capacity and boosting economic profitability.

Parallel output,compact structure,large output torque, smooth transmission, low noise,long lifetime

Mounting mode:foot-mounted,flange-mounted or torque arm-mounted.

Input mode:coupled motor,belted motor,input shaft or connection flange.

F Series Parallel Shaft Helical Gear Units Advantages

Product advantages:high modular design,making all the series apply fewer components, it can conveniently equip electric motor or other driving forces of various types.

The cabinet applies integral and high-strength casting mode, which has high rigidity and vibration resistance performance.

The gear unit applies low-carbon alloy steel quenching gear grinding process and shape-correction technology, making the products have larger bearing capacity. The operation is reliable, which can decrease noise and improve efficiency. Transmission ratio is divided into details, the scope is wide.

Combined type can obtain larger transmission ratio.

Gear unit is appropriate to be mounted at any space and any angle.